A year ago, over 1,000 workers lost their lives and more than 2,000 were injured in a catastrophic but avoidable industrial accident in Dhaka, Bangladesh. We now know how overcrowded the building was, and how its management ignored warning signs and failed to conduct proper inspections.

To be sure, this was not the first disaster in Bangladesh, nor is Bangladesh the only country where accidents occur, as experience from Cambodia, Pakistan and elsewhere shows.

A year later, what have we learned? That the situation hasn’t changed much. Are things better? Not appreciably so.

Global apparel brands have formed two initiatives that conduct mandatory, periodic inspections. While the initiatives – the Bangladesh Accord on Fire and Building Safety and the Alliance for Bangladesh Worker Safety – are well-intentioned, they rely on audits and inspection as a way to enforce change. While auditing is valuable, it is not sufficient, and it often addresses the problem when it may be too late to resolve, leaving the foreign brand with limited options, such as terminating the contract, where workers bear the burden through lost jobs.

Bangladesh has belatedly amended its 2006 Labour Act, which gives workers the right to form unions without seeking approval from their employers. The government’s decision to increase the minimum wage is also a good step, but there is need for a complete cultural and attitudinal change. Reforms have been slow because many factory owners are politicians themselves. The regulatory capture prevents more progressive measures, since parliamentarian/businessmen have little incentive to increase costs – of inspections, wages, or fines – that businesses would have to bear.

This is not to suggest that international brands should leave Bangladesh. Garments and textiles represent an important industry for Bangladesh, which has created millions of jobs and earns Bangladesh significant hard currency revenues. But it can no longer be business as usual, and companies – local and foreign – will have to raise their game significantly.

As the Centre for Business and Human Rights at New York University’s Stern School of Business points out in a report released to coincide with the anniversary today, “There are significant challenges to achieving the objective of a sustainable garment sector in Bangladesh. To date, too little attention has been paid to connecting the dots to provide an overall assessment of where things stand and what really needs to be done to ensure safer factories and better working conditions.”

Garments and textiles represent an important industry for Bangladesh, earning significant hard currency revenues. But it can no longer be business as usual.

The report identifies indirect sourcing as one of the major problems, where the lack of transparency adversely affects good governance. The pursuit of lowest nominal costs has led to heightened risks, undermined wages and work conditions, and slowed productivity improvement. The Accord and the Alliance also face criticism in the report for having established “parallel, and in some cases overlapping” systems of monitoring and worker training.

As the Dhaka Tribune reported on April 22, the inspections of these new initiatives have been slow and sometimes arbitrary, aimed at protecting reputations rather than providing a safe working environment. According to Transparency International Bangladesh, the Accord has produced 10 complete inspection reports so far, although it has visited some 80 factories in the last six months and recommended halting production in at least 10 factories. Besides, the newspaper report alleges that while a few factories have been ordered to close, money has not been sanctioned to pay wages to workers during the period of the factory’s closure, as was originally intended.

Furthermore, the Accord and the Alliance cover less than 2,000 factories – the ones that supply to participating brands. But there are more than 5,000 factories in the country, and many of those factories operate in far worse conditions than those found in the top-tier suppliers. The Accord and the Alliance have neither the mandate, nor the incentive, to inspect, or work with the bottom-tier factories. Who will do that? It is critical for donor governments to focus here, lest they be accused of caring only for companies whose products are available in their home markets.

The Bangladesh Government lacks the political will (partly due to the regulatory capture) and the ability (due to resource constraints) to fulfill its obligations. As a report in the Bangladeshi daily newspaper New Age showed last year, of the thousands of buildings in Dhaka, including residential apartments and office towers, fewer than a dozen had certificates to show that they met all safety and security requirements. Inspectors are few, they remain poorly paid, and they have thousands of factories to inspect, creating perverse incentives like bribery to overlook infractions.

Another obstacle can be seen in efforts to compensate victims of Rana Plaza. Of the US$40 million target, only US$15 million has been raised so far, and one firm – Primark – has contributed US$8 million of that total. Fifteen brands whose sub-contractors were in the building have yet to contribute anything. While most workers have received some compensation, many workers told Human Rights Watch that amounts are inadequate.

Besides, as the Stern Centre’s report points out, a major part of available funds support the International Labour Organisation and International Finance Corporation’s Better Work Programme. Corruption is a major issue in Bangladesh, so donor wariness at lavishing resources in Bangladesh is understandable, but by failing to create a way to channel resources where they are most needed, the international community runs the risk of circulating large amounts of money within itself – donors supporting international agencies which pay for foreign experts to audit and train local organisations, and international unions and civil society groups get funded to monitor or to participate in multi-stakeholder initiatives. Such activities are valid, but they don’t necessarily address the problem at its root, nor build financial or technical capacity among local companies and civil society groups.

It is critical that all parties, local and international – governments, businesses, unions, and civil society groups – use the first anniversary of the Rana Plaza tragedy to rededicate themselves to fixing the basic problem: working conditions in Bangladesh. Doing so will require a range of actions including:

-

Donor and importing governments should support locally-led efforts to improve safety standards and provide incentives to local companies to adhere to international norms;

-

International businesses should implement the UN Guiding Principles on Business and Human Rights throughout their operations and provide training and resources to their suppliers to help them meet international standards;

-

International trade unions should empower local trade unions so that they can monitor local operations so that those meet international safety standards; and,

-

International civil society should encourage consumers to demand from their favorite brands that workers are treated fairly, have the right of collective bargaining and forming unions, and receive fair living wages.

There is work to be done in Bangladesh as well:

-

The government will have to invest in inspecting and monitoring factories and regulate safety and security of the workforce, besides reforming laws that recognize workers’ rights;

-

Local manufacturers must invest in improving factory infrastructure and pay fair living wages to their workers, and recognize their right to form unions and bargain collectively;

-

Local trade unions must focus primarily on the interests of workers; and,

-

Local civil society organisations should provide legal aid and support to workers, in particular women and migrant workers, so that their rights are protected.

Real progress will also require the industry to rethink how it procures garments from Bangladesh. It means paying a higher price to local suppliers, so that they aren’t squeezed and are able to make the necessary investments using their own resources, and not depend on donor money. Consumers in rich countries will also have to start paying a more reasonable price for their T-shirts and jeans.

If it is in the interests of everyone for the international economy to keep growing, surely companies want today’s workers to be tomorrow’s consumers? Only a comprehensive approach will ensure that factories in future won’t burn or crumble, and workers will be well protected.

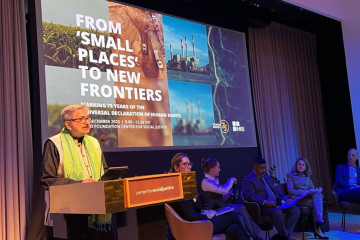

Photo: NYU Stern BHR

How should businesses respond to an age of conflict and uncertainty?

As 2024 began, European Commission President Ursula von der Leyen aptly summed up our deeply worrying collective moment. As she put it, speaking at the annual World Economic Forum in Switzerland, we are moving through “an era of conflict and...

26 March 2024 | Commentary

Commentary by Scott Jerbi, Senior Advisor, Policy & Outreach, IHRB